ECO-DESIGN

Sugar cane fiber

A New Range of Containers Eco-Designed using Sugar Cane Fibre

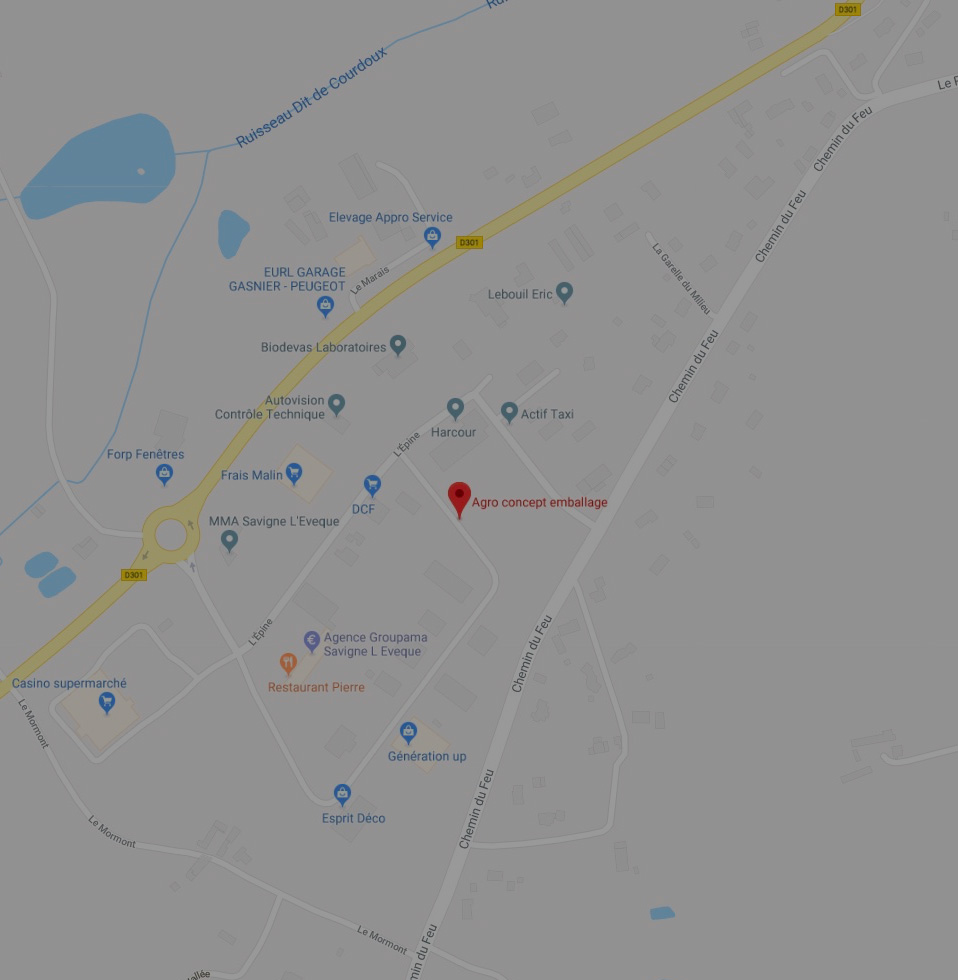

All AGRO CONCEPT EMBAL’s expertise has gone into eco-designing our sugar cane packaging. As such, they perfectly exemplify our capacity for innovation.

Technical specificities

Recyclable, biodegradable, compostable, compatible with all types of oven and suitable for freezing.

Temperature resistance + or - 220 degrees.

Usable in an industrial environment without having to modify the existing equipment.

Very low creation costs thanks to 3D plans and prints.

Reduction on the deadlines, costs of creation of mold thanks to the possibility of counter-typing the existing models.

Creation and design on computer with 3D visualization.

Because they are recyclable, biodegradable, compostable, compatible with all kinds of ovens and freezer-friendly,

they provide the perfect response to consumers’ and industrial producers’ needs.

The Environment is Our Key Concern

Although all our packaging is already environmentally friendly – our ceramics are reusable, and our glass and enamelled and stainless steels can be endlessly recycled – we wanted to go a step further in our fight to protect the planet.

Our new container range has been created using sugar cane production waste, making it a great solution to the agri-food industry’s increasingly advanced requirements while also guaranteeing food stays optimally preserved. By producing recyclable, biodegradable, compostable packaging exclusively derived from waste products, we’ve created a totally circular economy!

Multiple Agri-Food Applications

These new packaging options are lined with food-safe film (PE, PP or PLA) and are ideal for multiple different applications, including fresh produce, frozen products and ready meals.

Our film-free containers are recommended for fruit and vegetables.

They don’t require industrial manufacturers to change their existing equipment and their design costs are very low.

If your project is sent on to the relevant departments during planning and 3D printing, we can also reproduce existing models as a way of shortening timeframes and reducing design and mould-making costs.

How Does It Work?

Sugar cane is a plant that naturally regenerates several times a year. Once the sugar has been extracted, the stems and waste products are reclaimed so they can be processed into sugar cane pulp.

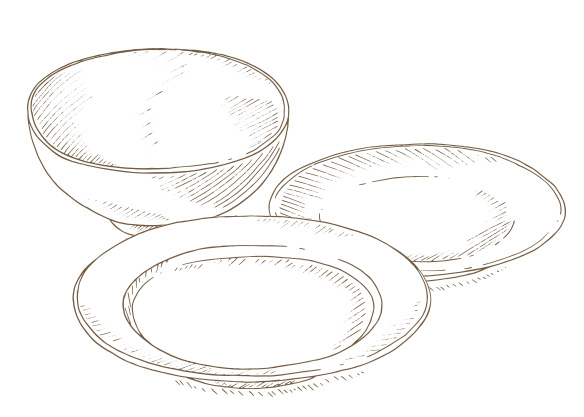

Where they were once left unused or burnt, by-products are now converted into pulp, then thermoformed and turned into environmentally-friendly crockery such as containers, bowls and plates.

Sugar cane pulp is sometimes known as sugar cane fibre and is commonly used in agri-food packaging (for food storage boxes, for example), as well as for electronics and even cosmetics. Its unique texture and natural scent stand testament to its environmental credentials. Sugar cane fibre makes it possible to produce cleaner packaging, and it is undeniably one of the best substitutes for plastic on the market right now.

Sugar Cane Fibre is one of the best substitutes for plastic today.